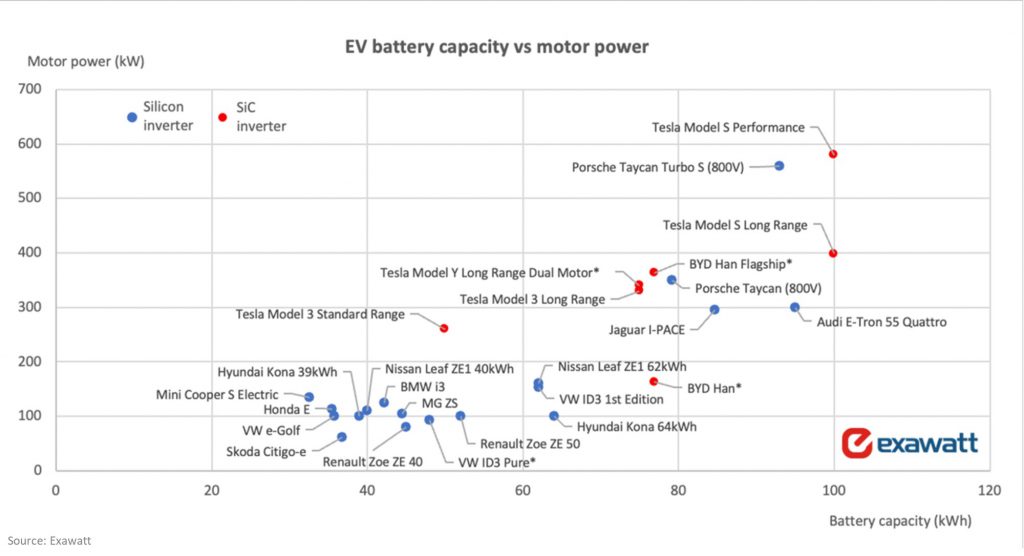

#Tesla (2017), #BYD (2020) and now #Hyundai (2021) are spearheading the transition towards a new age of #SiC powered EVs. SiC’s rising adoption is aimed at gaining the range advantage, which dominates most #EV discussions. With better #power conversion #efficiency than #Si, SiC based devices can increase vehicle range by 10% or more.

Today, majority of early adoption of SiC is in #BEVs with large #battery packs driven by savings on pack size as the typical cost of SiC based #powerelectronic systems exceeds that of Si based systems by $200 & increases with inverter power. Also, over past few years, SiC has grown rapidly – more acquisitions, capacity expansions, vertical integration – to enable custom devices for small scale/ high performance segments. Though as manufacturers continue to aggressively pursue better vehicle range, SiC components will witness more demand to manage higher voltages for high performance segments as well as for smaller/ lower cost vehicles. This wider market adoption will be enabled by growing maturity of #automotive supply chain & normalization of high rate charging.

In short, exciting times ahead as we can expect the SiC supply to catch up with demand over next few years & eventually, SiC to be used in almost all BEV powertrains by later this decade.